Chuda Videos

Videos

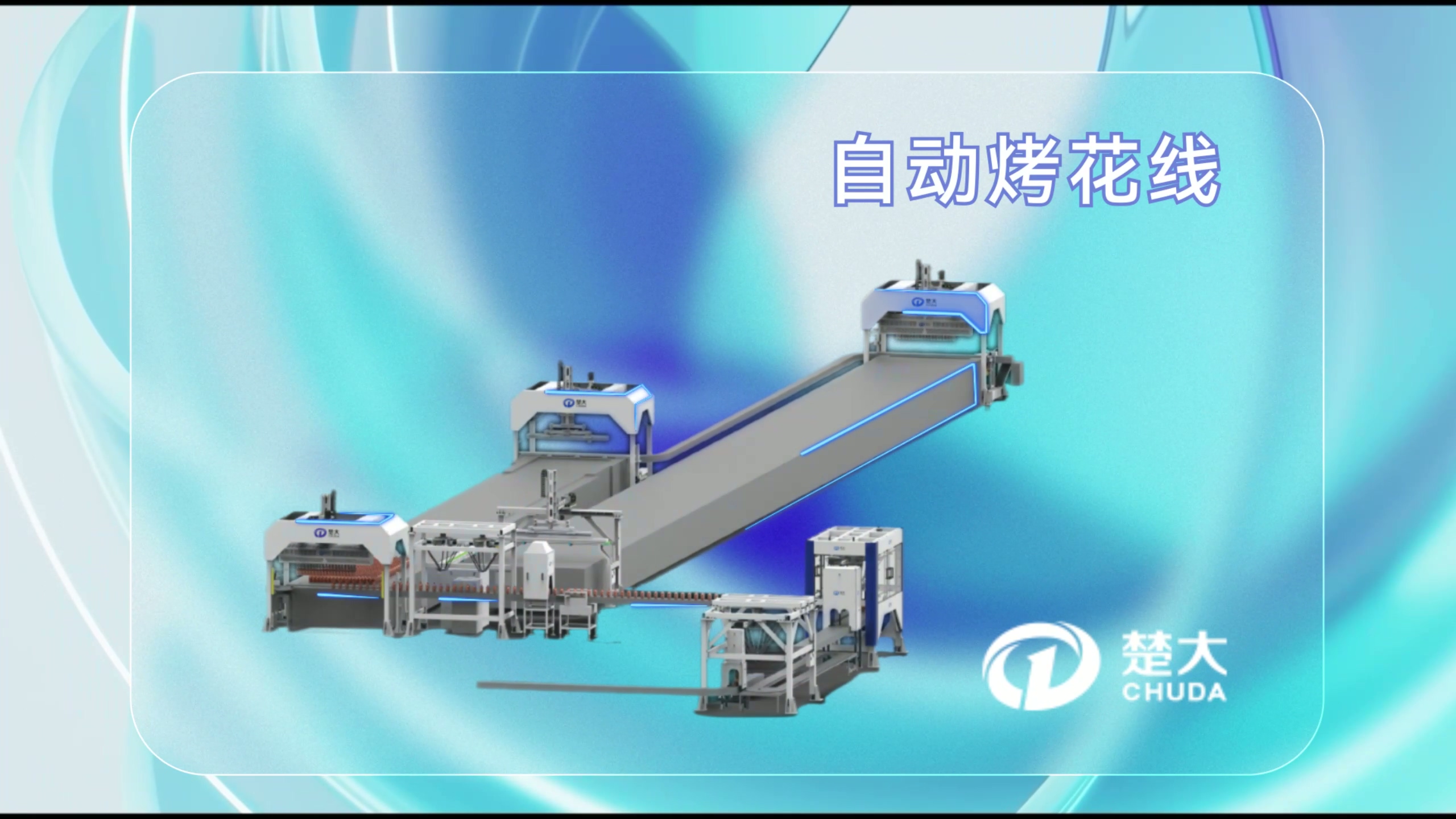

Automatic Decorating Line

Modular design, tailor-made for deep processing applications, enabling automatic capping/uncapping and loading/unloading in the deep processing of glass bottles and jars.

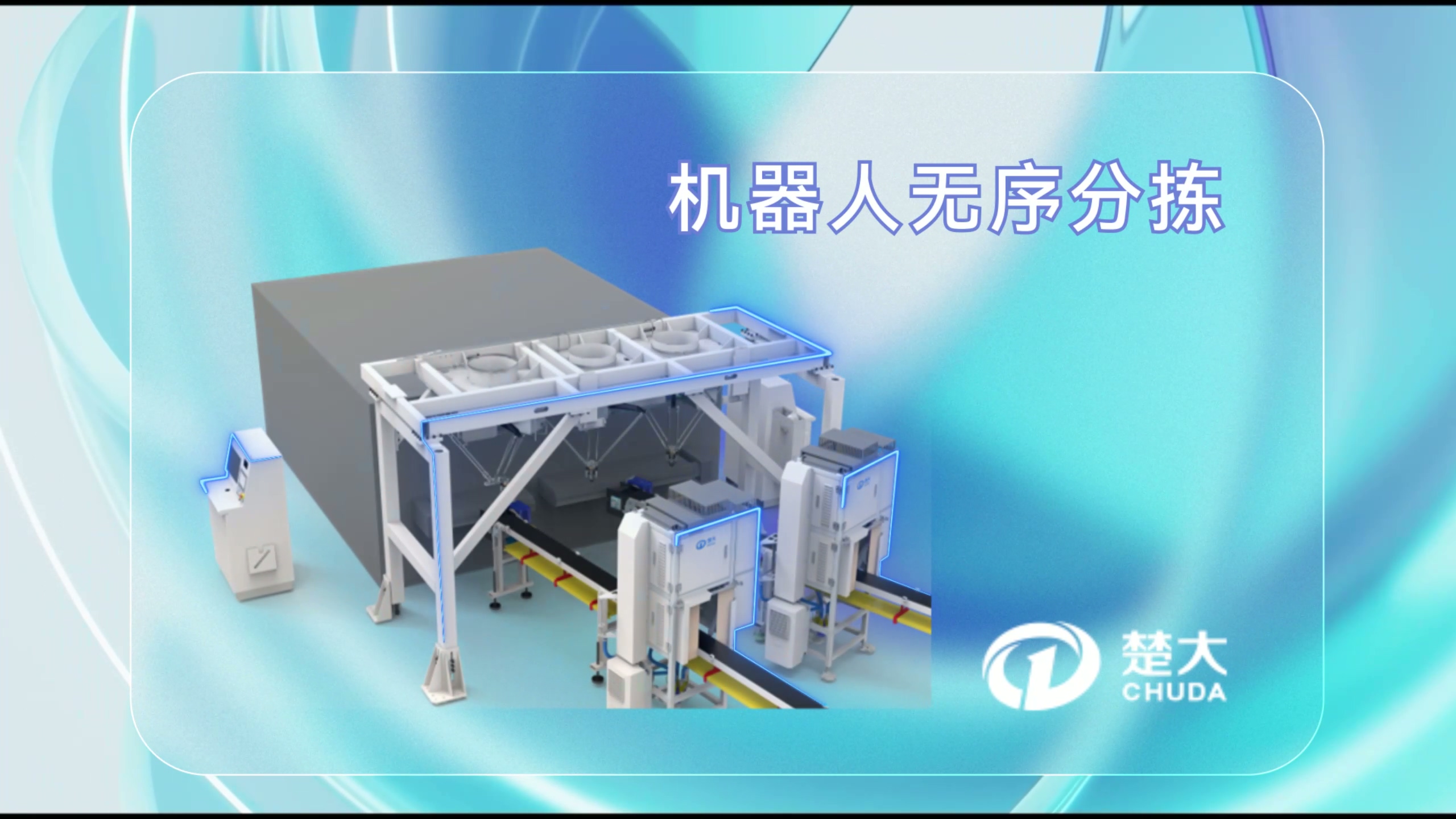

Robot Unordered Sorting

Using advanced vision tech and algorithms, it precisely identifies, grabs and sorts glass containers of various shapes for annealing lehr loading/unloading.

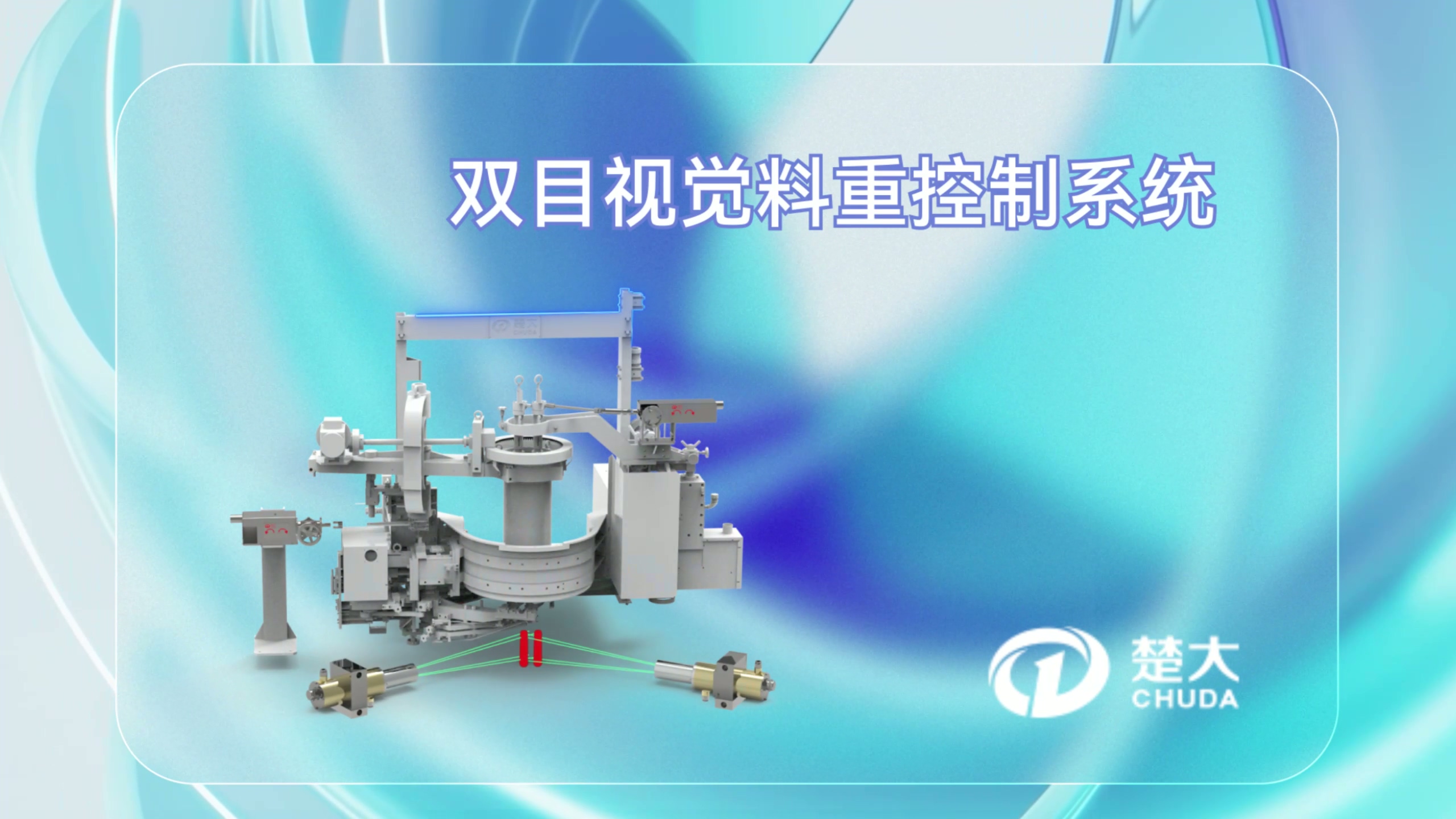

Gob Weight Control System

The vision system uses 3D modeling to calculate gob weight, enabling real-time closed-loop control for uniform gob formation.

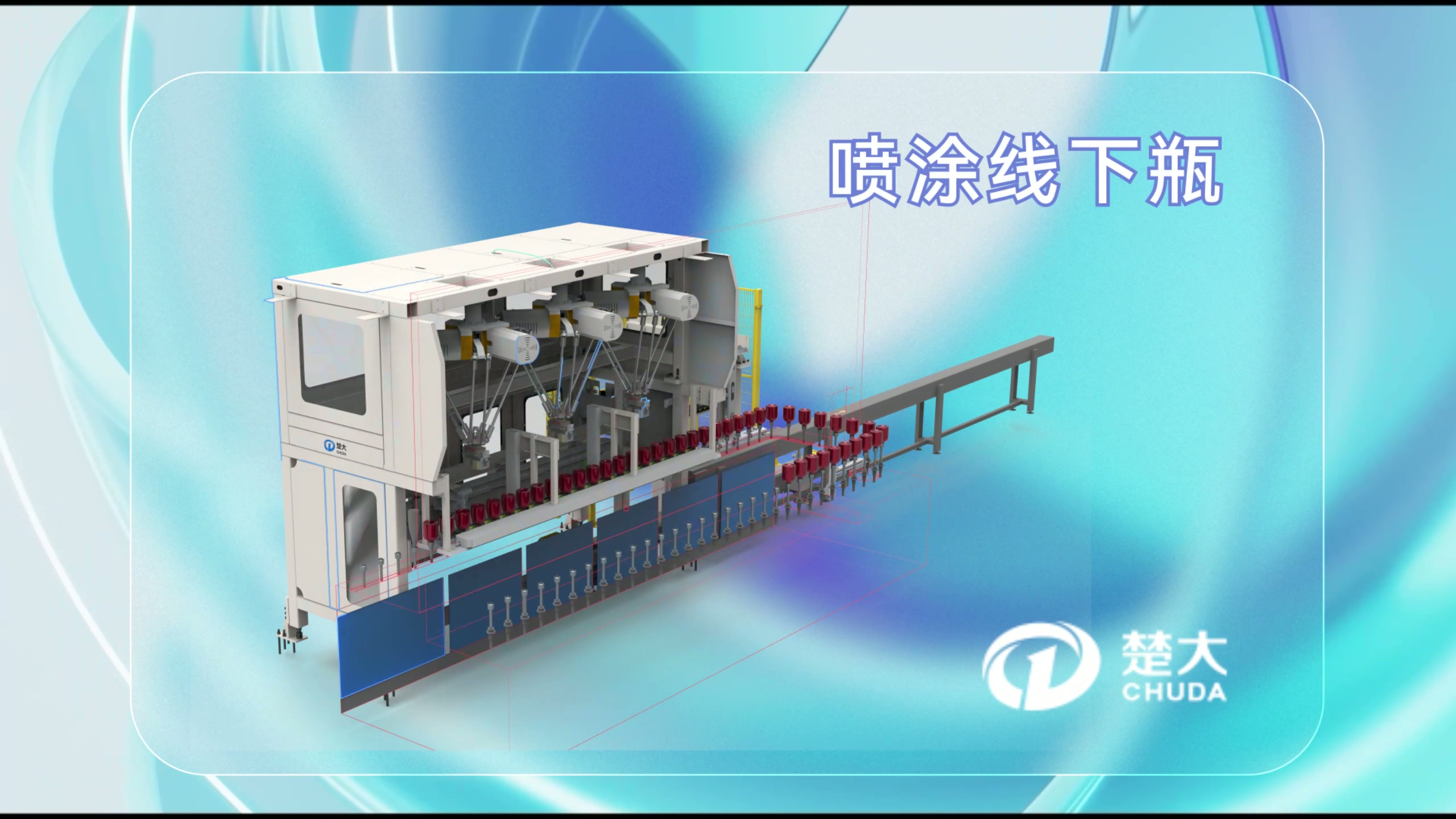

Robot Unloading on Spraying Line

Leveraging robots for efficient bottle unloading in glass bottle spraying lines, gantry grippers replace manual labor to transport glass bottles to the conveyor line.

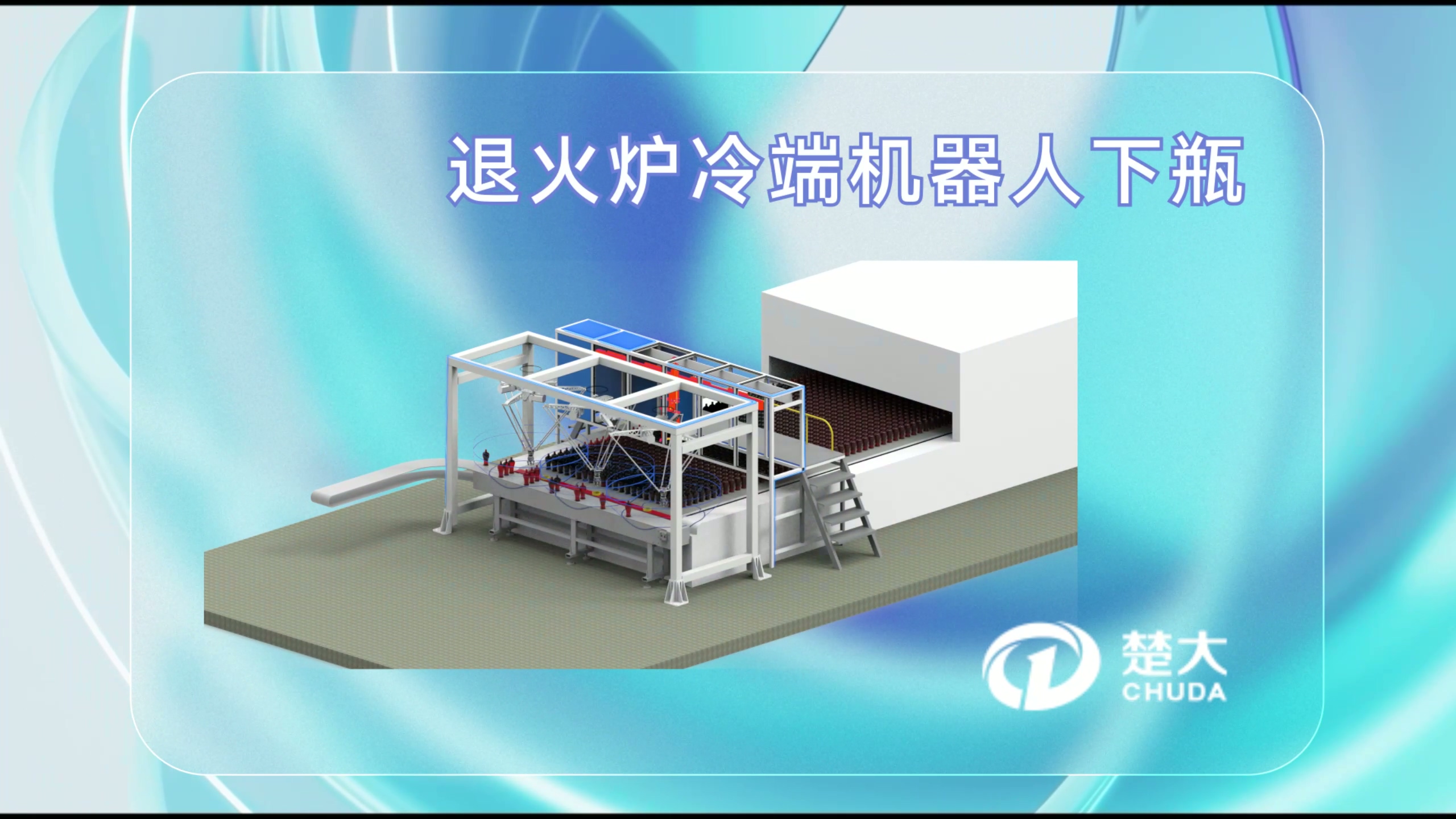

Robot Unloading at Cold End on Annealing Lehr

It replaces manual labor by automatically transporting bottles from the lehr to the conveyor, with adaptable setups for different unloading operations.

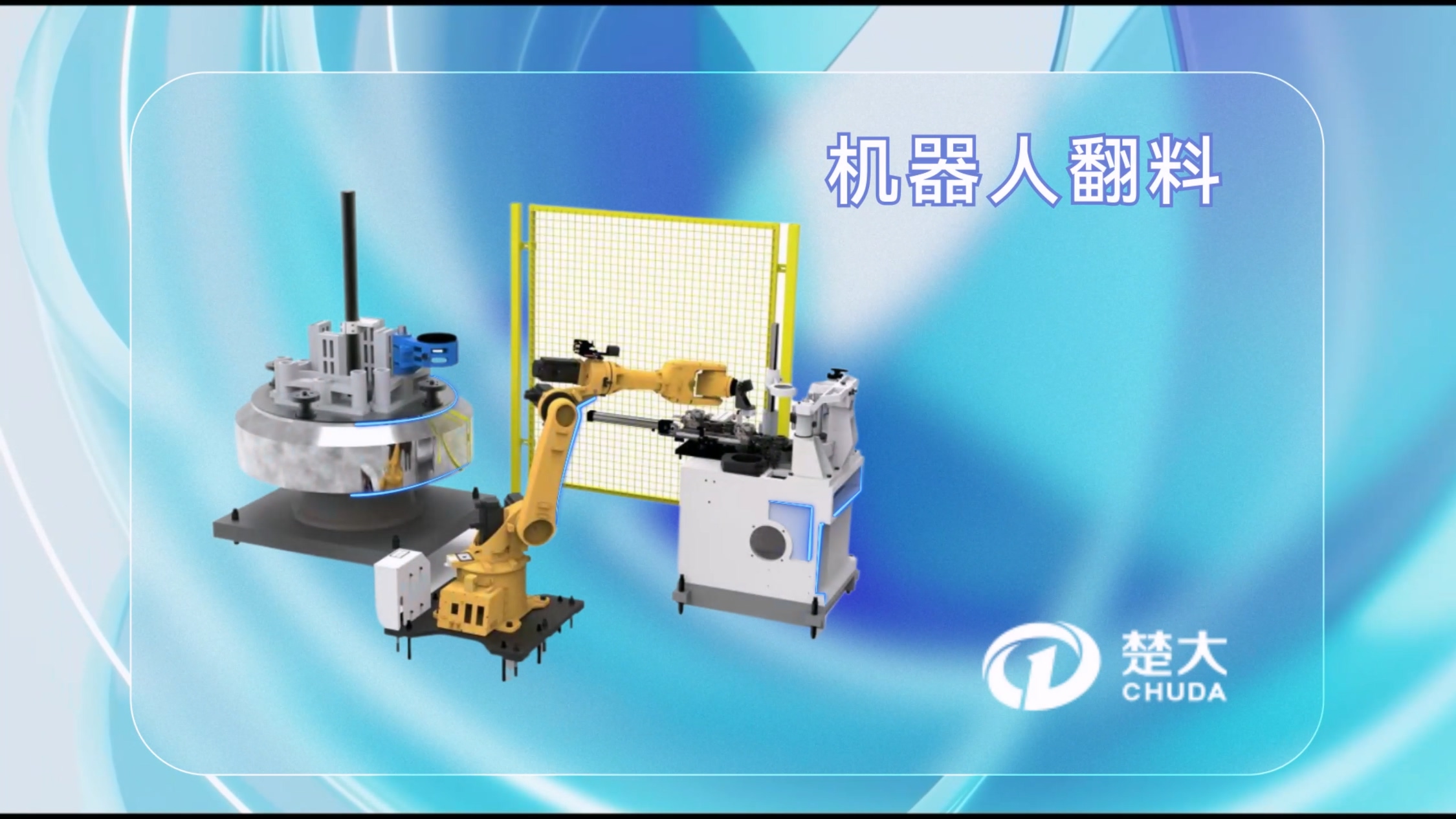

Robot Automatic Parison Inversion

An efficient and flexible solution uses precision robots to transfer parisons to blow molds, enabling the automated production of ringless glass bottles.

Unloading to Different Lines on Annealing Lehr

With visual-mechanical integration enabling high-speed dynamic gripping, it meets intelligent post-annealing sorting needs for continuous glass production.

Automatic Spraying Line

Robot-pneumatic gripper clusters enable fully automated spraying/transfer—no manual work in the process, improving line efficiency and product consistency.

Uncapping and Unloading on Glass Bottle and Jar Decorating Line

Gantry robot breaks manual safety & efficiency limits in production environments.

Pneumatic Gripper Uncapping

The integrated system enables automatic bottle cap removal and recycling.

Gantry Robot Unloading with Cap

The process flow of fully automatic grabbing, handling, and transfer for capped bottles and jars is achieved through the three-axis gantry robotic arms combined with a pneumatic gripper cluster system. The high-speed movement of the three-axis gantry integrates with pneumatic gripping, while the flexible design of the pneumatic gripper cluster adapts to various bottle types, ensuring grabbing stability.