Service & Support

Service Support

Project Consulting

With over 30 years of exclusive experience in the glass equipment industry, we offer complete production line technical guidance for your project planning.

Planning and Design

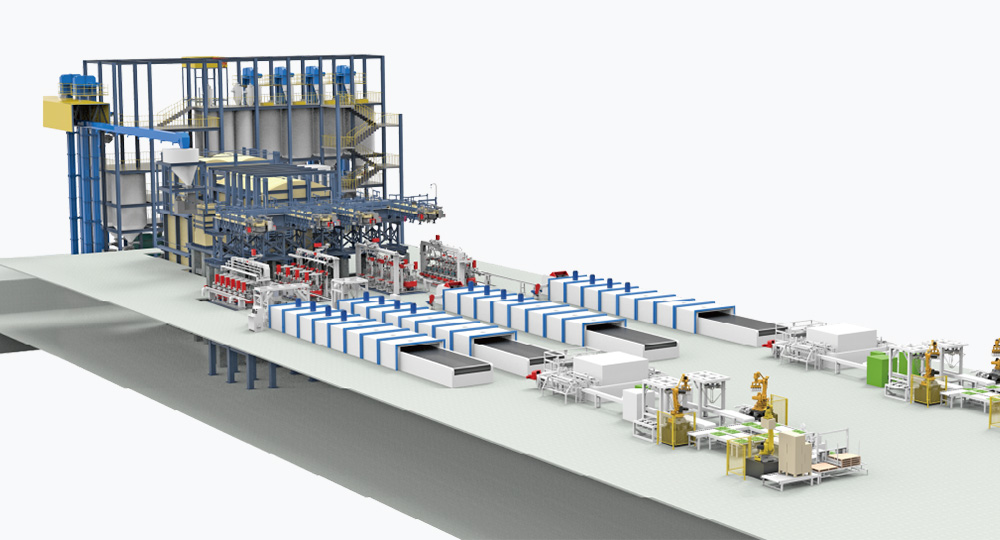

We offer upfront services including project consulting, factory planning, process scheme design, equipment selection, and investment estimation. Leveraging our extensive industry experience, professional expertise, and market insights, we provide tailor-made equipment selection recommendations and investment plans to empower clients in making precise decisions.

Manufacturing

Boasting an over 10,000 m² manufacturing workshop and with all core equipment independently developed and produced in-house, Chuda Intelligent has established a comprehensive manufacturing and quality assurance system. Equipped with advanced equipment such as MAZAK flexible production lines (FMS), 5-sided gantry machining centers, 12,000W fiber laser cutting machines, and 5-axis turning-milling composite machining centers, we achieve the manufacturing of high-precision and complex components, ensuring superior product quality and high production efficiency.

Installation and Commissioning

With years of customer service experience, our thermal engineering, mechanical, and electrical teams provide services such as equipment installation and commissioning optimization. From electrical performance debugging and precision calibration to equipment trial operation, we ensure stable equipment operation and deliver it to customers in optimal condition.

Operation Training

Chuda Intelligent has established a coherent training system for customers covering both pre-delivery and post-delivery phases. Before delivery, customers can visit our company where technical experts will explain equipment principles and demonstrate operations in professional venues. After delivery, on-site training at the production site will be conducted based on actual conditions, focusing on equipment startup, parameter setting, fault troubleshooting, etc. We guide customer operators through hands-on practice to ensure they master the skills proficiently and maximize equipment efficiency.

After-sales Services

Chuda Intelligent provides cross-disciplinary after-sales value-added services with 7×24-hour fault response. Our industry-experienced technical professionals assist clients in regular maintenance & inspections, on-site emergency repairs, and more.

Remote Service

Chuda Intelligent has built a 5G+ intelligent remote operation and maintenance platform by leveraging advanced 5G technology, providing customers with efficient and convenient remote equipment debugging and fault handling services to maximize trouble-free equipment operation.

Spare Parts

Based on years of customer service experience, Chuda Intelligent maintains a rich and well-stocked inventory of spare parts, covering key components for core equipment such as glass forming machinery and raw material batching systems. This ensures timely and reliable supply of wear parts to customers, minimizing unplanned downtime.

5G+ Industrial Internet Application

We have established a BI data central control platform for equipment products. Through 5G+ industrial Internet, we realize the collection, analysis and processing of equipment operation data and relevant fault data, providing data support for the company's products, reducing equipment failure rate, improving production efficiency and enhancing product quality.